Did you know that poor inventory control contributes to up to 35% of project cost overruns in the construction industry? Large-scale sites handle thousands of materials daily — steel, cement, pipes, safety gear, and machinery parts. One misstep can lead to delays, wasted materials, or even halted projects.

That’s where inventory management for construction sites comes in. With the right hacks and tools, you can prevent losses, optimize usage, and keep projects running smoothly. In this blog, we’ll explore proven strategies to manage construction inventory, avoid costly mistakes, and see how an integrated digital platform like OConstruction simplifies the process.

Business Relevance & Why It Matters

Construction projects are high-stakes. Every delay or material shortage translates into financial loss and strained client relationships. Managing inventory at scale isn’t just about storing materials—it’s about ensuring the right resources are available at the right time, in the right quantity.

Why should companies care?

- Cost savings: Proper material tracking reduces waste and theft.

- Time efficiency: Automated updates avoid last-minute procurement chaos.

- Compliance & safety: Some materials require regulated storage and usage documentation.

Who benefits the most?

- Project managers juggling multiple sites.

- Procurement teams negotiating bulk orders.

- Site engineers rely on timely supply delivery.

Real-world pain vs. solution:

- A high-rise project in Mumbai was delayed by 3 months due to the loss of shipments of steel bars.

- A highway project in Texas wasted 10% of the cement because of double ordering.

Both problems could have been solved with real-time inventory management for construction sites.

Best Practices, Frameworks, and Actionable Strategies

Do’s and Don’ts of Inventory Management for Construction Sites

- Adopt digital tracking systems – Manual logs are outdated and prone to errors. Digital systems ensure real-time updates.

- Don’t rely solely on contractors – Always verify supply counts with internal checks to avoid misreporting.

- Do set reorder thresholds – Automated alerts prevent stockouts or overstocking.

- Don’t overlook material expiry – Chemicals, paint, and safety gear often have shelf lives; expired items compromise safety.

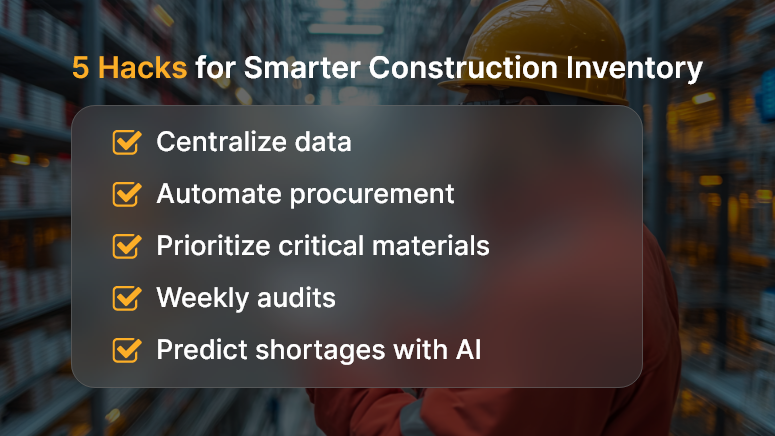

Quick Wins and Best Practices

- Centralize Inventory Data: Instead of scattered spreadsheets, use a centralized platform. It provides a single source of truth across all sites.

- Leverage QR Codes & RFID Tags: Tagging materials enables instant scanning and reduces manual counting errors.

- Automate Procurement Triggers: Link usage patterns with vendor systems for seamless reordering.

- Prioritize Critical Materials: Classify materials as high, medium, or low priority. Always buffer high-priority materials like steel, cement, and safety gear.

- Conduct Weekly Audits: Digital audits spot inconsistencies early, preventing large-scale losses.

Step-by-Step Framework for Large Sites

- Plan Before You Procure: Map project phases and align material requirements with timelines. This prevents both shortages and excess storage.

- Digitize Material Tracking: Use platforms like OConstruction for real-time inventory monitoring across multiple sites.

- Enable Multi-Site Visibility: Large contractors often manage multiple sites. With shared dashboards, managers can reallocate surplus materials instantly.

- Integrate with Financial Systems: Connect inventory with budget tracking. This helps align procurement with cost forecasts.

- Use Predictive Analytics: AI-driven insights forecast material demand and prevent last-minute supply gaps.

Customer Story

For example, BuildPro Constructions, a mid-sized infrastructure firm, used OConstruction’s real-time inventory tracking to streamline a highway expansion project. Previously, they faced frequent cement shortages, causing weekly delays. By digitizing their material flow and setting automated reorder triggers, they cut procurement delays by 40% and saved nearly ₹50 lakhs in wasted materials.

Here’s how:

- QR-coded shipments reduced theft.

- Real-time dashboards gave project managers live visibility.

- Predictive analytics flagged shortages before they became critical.

Key Takeaways & Closing Summary

Key Insights:

- Inventory management for construction sites is about accuracy, visibility, and efficiency.

- Digital tools replace guesswork with real-time insights.

- Preventing small errors today avoids massive delays tomorrow.

In summary:

Adopting smarter inventory practices isn’t optional — it’s a competitive edge. Large-scale projects demand precision, and the right platform ensures that every nail, brick, and beam is accounted for. By following the hacks outlined above, businesses can not only cut costs but also deliver projects faster and with higher quality.

FAQs

Q1. What is inventory management for construction sites?

Inventory management for construction sites refers to the process of tracking, controlling, and optimizing the use of construction materials, equipment, and tools across multiple projects. It ensures materials are available on time, reduces waste, and prevents costly project delays.

Q2. Why is inventory management important in large-scale construction projects?

Large-scale construction projects involve thousands of moving parts. Without proper construction inventory management, companies risk material shortages, overspending, and delays. Good practices reduce waste, optimize budgets, and improve project delivery timelines.

Q3. How does digital inventory tracking improve construction efficiency?

Digital inventory tracking provides real-time visibility into stock levels, locations, and usage. Features like QR codes, RFID tags, and automated reordering reduce manual errors, prevent theft, and save significant costs.

Q4. What are the common challenges in construction inventory management?

Typical challenges include:

- Overstocking or understocking materials

- Lack of real-time updates

- Miscommunication between project managers and suppliers

- Theft or material misuse

- Manual errors in spreadsheets

Using a digital platform addresses most of these issues.

Q5. Can inventory management software integrate with financial systems?

Yes. Advanced platforms like OConstruction can connect inventory with procurement and accounting systems. This integration helps align material purchases with budgets, track expenses, and forecast project costs accurately.

Q6. How do predictive analytics help in construction inventory management?

Predictive analytics analyzes historical data and project timelines to forecast future material needs. This prevents last-minute shortages, avoids storage costs for unused items, and supports smarter procurement decisions.

Q7. Who benefits the most from effective construction inventory management?

- Project managers – gain visibility across multiple sites

- Procurement teams – streamline supplier management

- Finance departments – track material expenses in real time

- Site engineers – ensure materials are always available when needed

Q8. How can OConstruction help with inventory management for construction sites?

OConstruction’s digital platform enables real-time tracking, automated reordering, multi-site visibility, and predictive insights. This means fewer delays, reduced costs, and higher productivity for construction businesses of any size.